Dealing with Bad Bunkers

According to Lloyd’s Register, fuel accounts for up to 60% of a ship’s operational costs and quality is vitally important. Off-specification or contaminated fuel can adversely affect performance and cause serious damage.

Even away from allegations and concerns about tainted or contaminated fuel, globally quality varies significantly. From the US Gulf to Singapore, there have been reports of vessels receiving tainted fuel. Which not only risks damaging machinery but can bring serious safety problems. A vessel blackout can cause all kinds of problems, from grounding to collisions, and if it happens in bad weather, even sinking.

According to a loss prevention report from NORTH P&I, the bunker fuel contaminations have affected numerous vessels, with problems ranging from failure of the fuel system to the auxiliary engine resulting in loss of power and propulsion creating a blackout.

Marine lawyers and P&I Clubs have been eager to flag the issues to clients and members, respectively. Stressing the fact that strict fuel testing rules are in place, with IMO guidelines (“Guidelines for the sampling of fuel oil for determination of compliance with Annex VI MARPOL 73/78”) which provide, amongst other things, that “a sample of the fuel delivered to ship should be obtained at the receiving ship’s bunker manifold and should be drawn continuously throughout the bunker delivery period”. However, it seems that even with IMO guidelines and ISO standards to follow (ISO 8217), it is clear that harmful compounds can slip through the checks.

Contamination can also cause long term problems, such as the seizure of fuel pumps and plunger and barrel corrosion. So even if a vessel does manage to cope unscathed in the first instance, there can be a long tail to the concerns.

Intertanko has long voiced its concerns about contaminated fuel and its view that not enough is being done to help shipowners. The trade body has called for governments and authorities to investigate fuel contamination cases and take appropriate actions, including giving serious fines together with restitution for the ships impacted.

Contaminated bunkers can lead to numerous technical problems for vessels. These include severe sludging at centrifuges, clogged pipelines and overwhelmed fuel filters. Blocked fuel filters are usually the first indicator that all is not well with the supply.

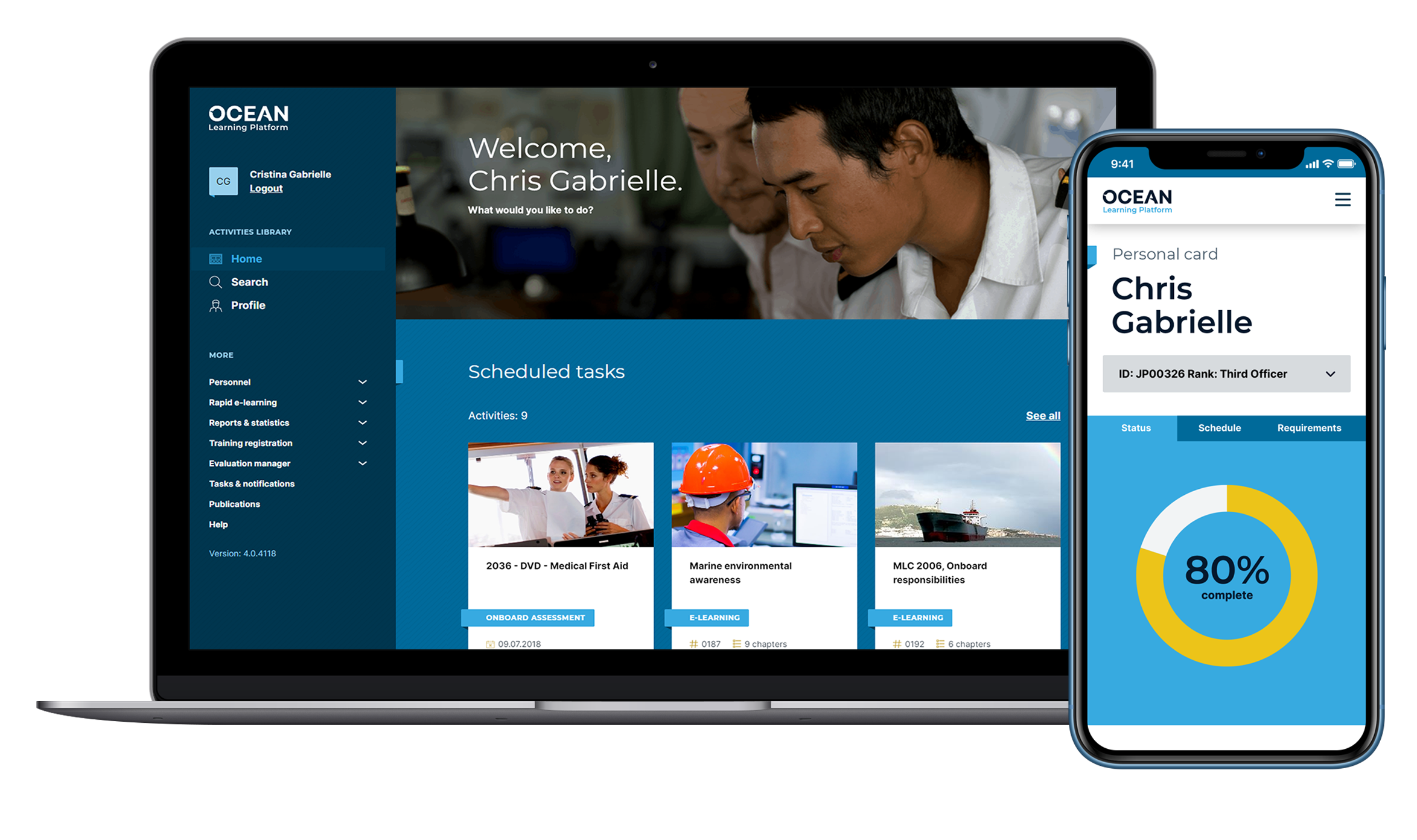

Unparalleled breadth and quality of content

We offer the most comprehensive library of maritime blended learning content ever assembled, with the full spectrum of learning needs covered.

We take a blended approach to content, including e-learning, videos for group viewing, interactivity in assessments and exercises to test the application of knowledge.

As the fuel works its way through the system, other problems then become apparent, such as:

- blocking and excessive wear of fuel separators;

- sticking and excessive wear of fuel injection pumps and fuel injectors;

- damage to engine piston rings and excessive wear of the pistons and cylinder liners.

Even where bunkers have been up to specification, there are many reports of swindlers cheating unsuspecting crews by short delivering, leading to paying for fuel that is not received.

The term used is “short delivery”, this is where suppliers deliver less product than appears on the bunker receipt, this is far from a new phenomenon within the bunkering sector. It has been estimated that just last year, short bunker supplies cost buyers, owners and charterers an estimated US$100M in Fujairah and US$150M in Rotterdam. Understanding the tricks of the trade, the tests that are needed and even the mechanism to protest are key to protecting a vessel and also an owner’s best interests.

Better bunkering steps

Check yourself

Does your HFO flow meter work correctly? Is it regularly serviced and calibrated? Maintenance of the HFO Flow Meter should be set out in the Planned Maintenance System (PMS), and details of what should be performed when and how should be detailed. Make sure it has and is.

Procedures

Understanding the correct procedure for bunkering is vital for the safety of the vessel and for preventing oil spill. There is the obvious potential for spills and fire, so these basics need to be dealt with. However, having full and complete understanding of the procedures means that bunkering good practice can be implemented and ensured. This helps to head off problems and ensure the right paperwork is evident in the event of a dispute.

Sounding

Making sure sounding pipes are in a fit state, and can be used properly is also key. Cases in which tapes have not been able to reach the bottom of tanks are all too common, and mean that there is no way of actually ensuring the right calibration and filling. Knowledge passed down about the characteristics of the sounding pipes is important too – lessons from other crew can save problems. Rusting is a problem, and corrosion especially on bulk carriers can lead to ingress of dry, dusty cargoes.

Cleaning

Tank cleaning is vital. Ships on which tanks are not regularly cleaned can have surprisingly large amounts of sludge – sometimes running to tonnes. The process of cleaning means that there is less likelihood of under loading, bunkers are not contaminated in the tanks. An important part of this is also tank inspection, so that a true understanding of the state of the tanks can be ascertained, and remedial action taken if needed.

Sampling and testing

The key to avoiding bad bunkers is, of course, sampling and testing. The sooner an issue with bunker quality can be detected, the sooner remedial action can be taken to limit the severity of impact. Samples must be correctly gathered, labelled, and sealed before being sent to shore for laboratory testing. A robust procedure for collecting and testing samples provides peace of mind and ensures that reliable evidence is available should an issue or dispute relating to bunker quality arise.

The focus on ensuring a good, honest supply and testing is paramount, Ocean Technologies Group offers a wide range of bunkering materials. Which improves awareness and reduces risks related to bunkering operations, and the need for proper sampling and monitoring to detect bad bunkers. Find out more at our Ocean Learning Library https://library.oceantg.com/

The ultimate in maritime e-learning

Accessible, repeatable, measurable – a learning solution for the 21st century vessel, available wherever you are in the world.