Fire Safety

Fire Safety is the most common deficiency found in control inspections, accounting for around 15% of all deficiencies.

Since the beginning of 2020, at least 356 detentions were directly caused by one or more fire safety-related deficiencies, resulting in over 3000 days of lost time globally.

In other words, at least two vessels were detained in port every day in the last three years due to fire safety deficiencies.

With the 2023 Concentrated Inspection Campaign (CIC) putting vessel fire safety under even greater scrutiny, we’ve taken a deep dive into Port State Control (PSC) and our learning data to pull out insights to help you understand and mitigate risks to your crew and operations.

The analysis and conclusions that follow are based on the period of 1st Jan 2020 to 19th May 2023.

What is covered in this article?

- Which vessels are at the highest risk of fire-safety-related deficiencies?

- What are the common fire-safety-related deficiencies?

- What do ‘top’ and ‘bottom’ performing companies do differently?

We start by looking at the vessels, their characteristics, and their behaviour to determine if age, type and the ports called at have an impact on PSC fire-safety performance and understand vessels were more likely to receive fire-safety-related deficiencies.

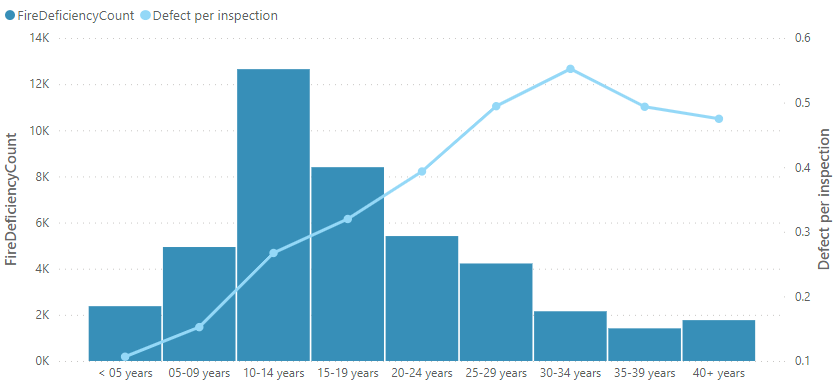

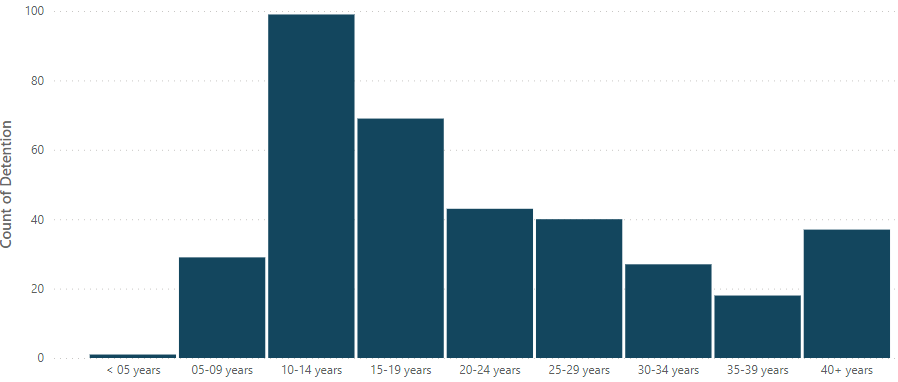

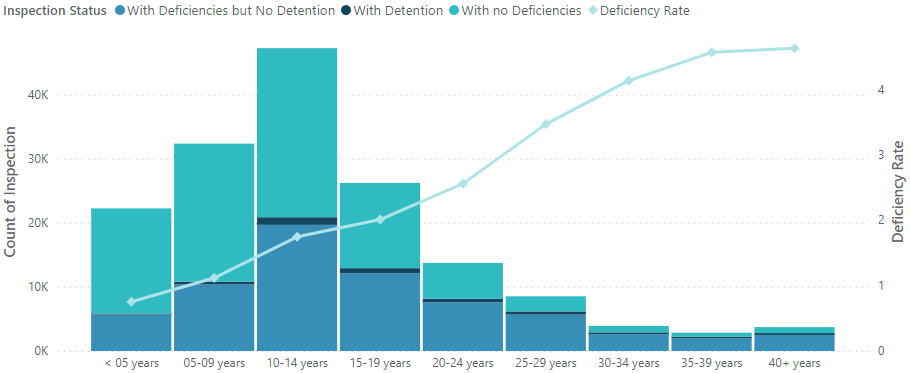

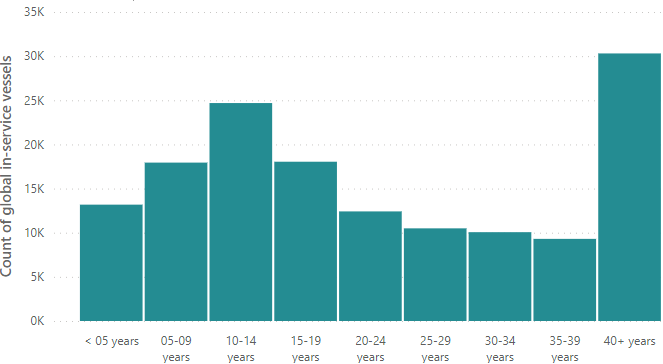

Age plays a role

The majority of the ‘fire-safety related’ deficiencies, as well as detentions, were found onboard vessels between 10 and 14 years old.

It is important to consider that far more vessels in this age group were inspected over the period, as the global average age of vessels is NEED NUMBER.

Vessels between 30 and 34 years old were the most likely to receive fire safety-related deficiency per inspection.

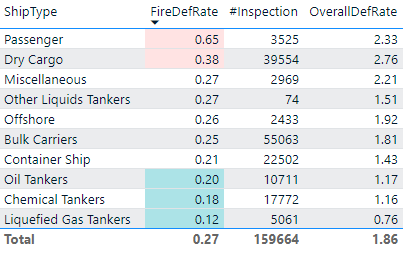

Wet vessels on top

Comparing wet and dry segments, wet vessels appeared to perform better.

Over 33,000 inspections, wet cargo vessels had an average fire deficiency rate 0.18. In the same period, dry cargo vessels had a fire deficiency rate of 0.29 (from 117k inspections).

Looking at fire-safety deficiencies across all vessel types, Passenger vessels had 2.4 times more fire-safety-related deficiencies per inspection compared to the industry average.

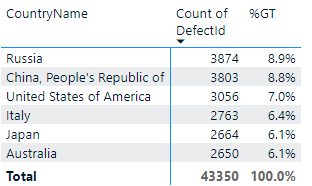

Deficiency rate varies by country of inspection

The top three countries where the most fire safety-related deficiencies were found are:

- Russia (8.8%)

- USA (8.5%)

- China (8.3%)

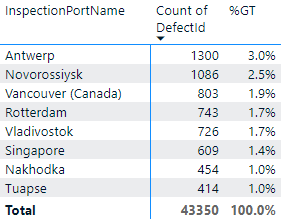

When looking at individual ports, the top three ports are

- Antwerp, Belgium (3%)

- Novorossiysk, Russia (2.5%)

- Vancouver, Canada (1.9%).

Moving on, we start to unpick the differences between the better and worse performing vessels.

The first thing to note is that OTG customers outperformed industry averages for fire safety criteria in PSC inspections.

Deficiencies

OTG customers had fewer fire-safety-related deficiencies during inspections, with a fire deficiency rate of 0.17 compared to the non-customer deficiency rate of 0.32. The outperformance is overall consistent year-on-year.

Detentions

OTG customers outperformed non-OTG customers, with that latter being three times more likely to be detained due to fire safety-related deficiencies. Additionally, when a fire safety-related detention occurred, non-customers spent an average of 8 days more in port, compared to OTG customers.

Competency Management System

Drilling down into the OTG customer data, we can see that vessels that had implemented the Competency Management System (CMS) performed better than OTG customers not using CMS.

This picture is consistent across both wet and dry cargo sectors.

Looking now at the specifics of the PSC inspection criteria, what are the most commonly cited fire-safety-related deficiencies?

Currently, there is a total of 27 detailed deficiencies under the Fire Safety category.

The top five identifiable areas of deficiency:

- Fire doors/openings in fire-resisting divisions

- Fire fighting equipment and appliances

- Fire detection and alarm systems

- Fixed fire extinguishing installation

- Fire-dampers

Behaviour plays a key role

The areas of deficiency noted above are consistent regardless of the age or type of vessels.

Although on the surface they all look to be directly related to shipboard equipment or the condition of the vessel’s structure, deficiency remarks from PSC inspectors (where provided) suggest a certain degree of human element involved, e.g., where they have identified that fire doors were held/tied, alarm systems had been turned off, etc.

Comparing the top and bottom performers

To understand what high-performing companies are doing differently, our Insights Team looked at the OLP usage of companies with 10 or more vessels that had no fire safety-related deficiencies over the period to see how it tracked against PSC fire-safety performance.

They found that:

The top 5 performing OTG customers used the Crew Evaluation System (CES), with 3 out of 5 of these customers evaluating company-specific knowledge.

- 2 out of 5 top performers have implemented CMS, whereas none of the bottom performers do.

- Top performers appear to have highly engaged crew with 94.5% active users with activity, whereas low performers only have 5.2% active users engaged. (Overall average: 70.6%)

- 96% of the top-performing customers’ vessels have OLP Service Pack 30 (or above) installed onboard, whereas only 69% of bottom performers’ vessels are up to date. (Overall average: 80%)

- 71% of top performers’ L&A records were from group activities – group activities include drills. The bottom performers invested only 1.8% of their learning & assessment activity in group exercises. (Overall average: 28%)

Summary of findings

1. Vessels that are more likely to receive fire-safety deficiencies were:

a. aged 10 years and above

b. passenger vessels

c. inspected in either Russia, China, or USA.

2. OTG customers outperform the industry average.

3. OTG customers who have implemented Competency Management System (CMS) outperform OTG customers that do not use CMS

4. Over 90% of the fire deficiencies found in the last 3.5 years relate to structural / equipment

5. Top performing companies appear to:

a. operate younger aged vessels

b. keep OLP up-to-date

c. attend more group sessions (including drills)

d. commit more fire safety-related activities

Takeaway: Use the tools at your disposal

Regardless of vessel age, type or port called at, it is possible to reduce the risk of detention by raising awareness of risks and responsibilities.

OLP has a wealth of resources and features that our top-performing customers are using to promote better behaviours and improve their PSC performance.

In the short term, the ongoing CIC is the perfect opportunity to run a campaign with your crews that reinforces the importance of fire safety.

Beyond ensuring that fire-safety training is completed, you can use company-specific communication through Company Notices and Rapid E-learning.

Both tools boost crew engagement and give you a trackable record of who has seen what you have sent or assigned to complete.

The OLP Mobile App is a free way to give your crew access to the content in your training library, whenever and wherever they need it. You can find more details about it here.

Takeaway: Make sure your OLP is up to date

OLP and the learning library are regularly updated to improve functionality and to ensure that the information in the learning material covers all changes to rules, standards, and best practices.

Updating OLP to the most recent version will ensure your crew have the most relevant and effective learning available.

Which learning solutions can be considered as part of preventive actions?

To foster a safe shipboard environment that is free from fire hazards, we rely on a group of crew who are capable of:

- identifying fire hazards and mitigate the unsafe acts / conditions accordingly

- masterising fire-fighting procedures, including operation of fire-fighting equipment

- inspecting and maintaining fire safety related structure / equipment.

In order to develop and retain crew competence related to fire safety, we recommend that you:

- refresh and re-validate knowledge about fire safety via self-study elearning

- reinforce preparedness of fire fighting via gamified learning and drills

- remain vigilant of fire hazards by regular case study and reflective learning as a group

- refine inspection and maintenance skills by learning on-the-job and seeking feedback.

Ocean Technologies Group has a wide range of learning solutions that can facilitate the learning needs of your seafarers, from off-the-shelf learning modules, company specific learning and assessments, to holistic competency management solutions.